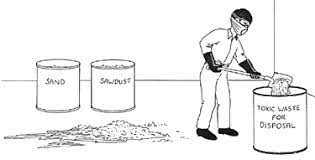

Removal and storage of toxic material

Courtesy : csbsju.edu

Even chemicals that are generally considered to be benign have potential to be hazardous under specific circumstances. Lab staff should ensure that stock chemicals and other hazardous materials are stored properly in order to prevent spills, uncontrolled reactions and minimize worker exposures. Labs are particularly challenged because of the number and variety of chemicals that are handled.

Regulatory Considerations

EPA regulation of hazardous chemicals is limited. Most regulation of these materials is by OSHA. These regulations address:

- Storage and handling of flammable liquids (29 CFR 1910.106);

- Storage of compressed gases (29 CFR 1910). This standard incorporates by reference, Compressed Gas Association Pamphlets C-6 1968 and C-8 1962; and

- Communicating chemical hazards to employees under the Laboratory Standard (29 CFR 1910.1450) and the Hazard Communication Standard (29 CFR 1910.1200).

Most state, tribal or local jurisdictions address hazardous material storage through the use of building codes which can incorporate BOCA Codes (Building Officials and Code Administrator), NFPA Codes (e.g., NFPA 10, 30, 45 and 101), and UBC (Uniform Building Code).

In addition to OSHA and building code requirements, hazardous material requirements are also promulgated by the DOT (49 CFR 171-179 and 14 CFR 103).

Management Issues

In order to effectively manage chemicals, small labs should establish a program based on the following three principals:

- Minimize Exposures Take the necessary precautions when working with and storing chemicals. As a means of minimizing the potential for exposure, pursue opportunities for product substitution.

- Do Not Underestimate Risks Ensure that the risk associated with each chemical is assessed, understood and communicated. It is prudent to assume all chemicals are hazardous and handle them accordingly.

- Use Proper Control Measures Eliminate the hazard through engineering controls, personal protective equipment, and administrative procedures. Ensure that all staff are properly trained in accordance with regulatory requirements (e.g., Laboratory Standard) so that they can operate safety at their job.

The following are key management issues for the storage and handling of hazardous materials including hazardous chemicals, flammable liquids, and compressed gases. Regulations regarding the proper storage of hazardous materials are complex. The information provided below is not comprehensive. Small lab managers should review OSHA and other requirements and guidelines described above to ensure that all requirements are being meet and that hazardous materials are being managed in accordance with prudent practices.

The Chemical Hygiene and Hazard Communication Plan

29 CFR 1910.1450 and 1910.1200 establish requirements for the communication of chemical hazards to employees in the workplace. The programs include a number of common elements. These are:

- Establishment of documented programs. For labs subject to the Lab Standard, this is in the form of a Chemical Hygiene Plan (CHP);

- Preparation and periodic update of an inventory of all hazardous chemicals;

- Labeling of all containers of hazardous chemicals (including materials transferred from the manufacturer’s container to end user container such as spray bottles);

- The availability of Material Safety Data Sheets (MSDS’s) for workers on all shifts and in all locations;

- Employee chemical hazard training and documentation; and

- Processes to review and update the program on a periodic basis.

The Lab Standard also requires that a Chemical Hygiene Officer (CHO) be designated by the lab to implement and maintain the program.

The Chemical Inventory

A chemical inventory should be prepared and maintained. The inventory is important in complying with OSHA requirements such as the Lab Standard and EPA requirements such as those under EPCRA (see Emergency Planning and Community Right-To-Know, Section 3.9). The inventory can also be helpful in conserving space, saving economic resources, and promoting P2 (see Hazardous Wastes, Section 3.3). Inventories should include chemical names, storage locations, quantities, and hazard information. Individual inventories should be maintained in each lab and storage area with a roll-up inventory maintained by the CHO or other appropriate environmental staff.

Chemical Storage in the Lab

Centralized chemical storage is recommended. Chemical storage inside labs should be limited to those chemicals and quantities necessary to complete task requirements. Key consideration for lab storage and handling include:

- Chemicals should not be stored on floors or benches since they could be knocked over. Storage on open shelves should be avoided. When necessary, lips or restraining devices should be used. Do not store chemicals in the lab above eye level;

- Chemicals should be segregated according to chemical classes and compatibility first. Then they can be stored by a convenient finding method such as alphabetically. For example, acids should be kept separate from bases, oxidizers from organics, and cyanides from acids. Physical separation should be provided for reactive chemicals. Use secondary containers in storage areas if available space does not allow incompatible materials to be properly separated;

- Properly store flammable and combustible materials in accordance with NFPA 45 and NFPA 30 (see further descriptions below);

- When possible, segregate toxic chemicals from other chemicals and store in closed cabinets. Label the cabinets “TOXIC CHEMICALS” or with a similar warning;

- Maintain chemicals per manufacturer requirements;

- Ensure containers are labeled in accordance with the OSHA Laboratory Standard;

- Make sure containers are closed when not in use;

- Use secondary containment such as acid carriers when transporting liquid chemicals more than a very short distance; and

- Central chemical storage areas (e.g., rooms) require specific design and equipment such as construction materials, lighting, ventilation, fire extinguishers, and housekeeping procedures such as aisle space.

Flammable and Combustible Liquids

Additional requirements apply to those chemicals that are classified as flammable or combustible liquids. These materials must be stored in accordance with NFPA 45 in labs and NFPA 30 in other locations.

- Regardless of experimental or production requirements and even when NFPA allows higher quantities, prudent practice is that the quantity of these materials in a lab room not exceed a total of 60 gallons or one months supply (for all such chemicals combined);

- Flammable and combustible liquids should be stored in glass, metal or plastic containers that meet NFPA requirements. More than 10 gallons of flammable and combustible liquids should be stored in a flammables cabinet or specially designed room. Prudent practice is to store these materials in a flammables cabinet when ever possible;

- Storage in flammable cabinets must not exceed design quantities (e.g., 60 gallons). Cabinets should be properly vented if there is the potential for the buildup of hazardous vapors; and

- Refrigerators and freezers used to store flammable liquids should be explosion proof or “lab safe” in accordance with NFPA 45.

Highly Reactive Chemicals

Labs that use highly reactive chemicals should take measures to ensure that these substances are handled properly. Due to the volatile and explosive nature of this class of chemicals, it warrants special attention. The following guidelines should be followed when using and storing highly reactive substances:

- Consider the storage requirements of each highly reactive chemical prior to purchase and make sure that staff are trained to store it safely;

- Obtain and review the Material Safety Data Sheet or other chemical safety information to ensure that staff are aware of the hazards and storage requirements;

- Purchase small quantities of the chemical that staff will need for the short term. Try not to exceed a three-month supply;

- Label, date, and inventory all highly reactive materials as soon as they are received. If staff must transfer the chemical from its original container into another container, make sure it is labeled with the name of the chemical, and the words “DANGER! HIGHLY REACTIVE MATERIAL.” For water reactive chemicals include the warning “DO

- NOT USE WATER TO EXTINGUISH FIRE.” Note: OSHA may require special labels disclosing all hazards on repackaged containers;

- Do not open a container of highly reactive material that is past its expiration date;

- Do not open a liquid organic peroxide or peroxide former (e.g., picric acid) if crystals or a precipitate are present;

- Segregate the following highly reactive materials:

- Oxidizing agents from reducing agents and combustibles,

- Powerful reducing agents from readily reducible substrates, and

- Acids from reducing agents;

- Store highly reactive liquids in trays large enough to hold the contents of the bottles;

- Store peroxidizable materials away from heat and light;

- Do not use metal spatulas to handle peroxides because ontamination by metals can lead to explosive decomposition. Use ceramic, Teflon, or wooden spatulas;

- Avoid friction, grinding, and all forms of impact near peroxides, especially solid peroxides and diazomethane solution (used in methylation of some pesticides). Glass containers that have screwcap lids or glass stoppers should not be used. Instead, use polyethylene bottles with screw-cap lids;

- Store materials that react vigorously with water away from possible contact with water;

- Store thermally unstable materials in a refrigerator. Use a refrigerator with these safety features:

- Alarm to warn when temperature is too high,

- Spark-proof controls on the outside, and

- Magnetic locked door;

- Store liquid organic peroxides at the lowest possible temperature consistent with the solubility or freezing point. Liquid peroxides are particularly sensitive during phase changes;

- Inspect and test peroxide-forming chemicals periodically; and

- Store containers in cabinets that are designed to hold that type of waste.

Compressed Gases

Compressed gas cylinder storage should meet the requirements in the Compressed Gas Association Pamphlets C-6 1968 and C-8 1962.

- Properly label the cylinders with their contents; store upright and away from heat sources;

- Cylinders should be chained to the wall or otherwise secured from falling;

- Do not store cylinders so as to block exits, obstruct aisles, or otherwise interfere with egress; and

- Cylinders should be separated based on their contents. Incompatible materials (e.g., oxygen and propane, chlorine and helium) should be segregated. In addition, full, partially full and empty cylinders should be labeled as to their status and separated.

Pollution Prevention and Hazardous Materials Storage

P2 and waste minimization for hazardous chemicals starts with the substitution of less hazardous substances (see Hazardous Wastes, Section 3.3). Sometimes this is difficult in a lab environment where researchers may be unwilling to change because they are concerned about the performance of the substitute in their experimentation. This can often be overcome through a team effort involving the CHO, environmental staff, purchasing staff and the researcher. In this setting, limitations and concerns can be clearly articulated and more easily addressed. Other opportunities include:

- Maintaining an accurate inventory that can be shared throughout the facility. Using this inventory, chemicals can be shared and expiration dates can be tracked;

- Purchasing of only the smallest amounts needed. Often, the additional cost associated with the smaller or custom purchase is less than the cost of expired or unused chemical disposal;

- Establish a centralized purchasing program to ensure full utilization of chemical products;

- Order reagent chemicals only in amounts needed;

- Maintain a limited inventory of chemicals on hand so those chemicals do not expire or deteriorate and necessitate disposal;

- Scale down experiments or procedures. Over the last decade, microscale chemistry has come to be considered a proven technology. It can reduce the quantity of chemical reagents used by a factor of 100 to 1000. Lab safety can be improved due to the reduction in exposure to organic vapors, for example, and spill preparedness is easier. Less chemical storage space is needed and chemical inventory management requires less labor. Cost reductions also result even if per-unit reagent costs increase due to purchasing smaller containers, the annual dollar savings on total purchases usually offsets this. Reduce or eliminate the use of highly toxic chemicals in lab experiments;

- Increase the use of instruments that require less reagent or smaller or fewer samples;

- Use less solvent to rinse equipment;

- Review the use of highly toxic, carcinogenic, reactive, or mutagenic materials to determine if safer alternatives are feasible; and

- If feasible, consider using computer simulation or modeling to replace wet chemistry.

Even chemicals that are generally considered to be benign have potential to be hazardous under specific circumstances. Lab staff should ensure that stock chemicals and other hazardous materials are stored properly in order to prevent spills, uncontrolled reactions and minimize worker exposures. Labs are particularly challenged because of the number and variety of chemicals that are handled.

Regulatory Considerations

EPA regulation of hazardous chemicals is limited. Most regulation of these materials is by OSHA. These regulations address:

- Storage and handling of flammable liquids (29 CFR 1910.106);

- Storage of compressed gases (29 CFR 1910). This standard incorporates by reference, Compressed Gas Association Pamphlets C-6 1968 and C-8 1962; and

- Communicating chemical hazards to employees under the Laboratory Standard (29 CFR 1910.1450) and the Hazard Communication Standard (29 CFR 1910.1200).

Most state, tribal or local jurisdictions address hazardous material storage through the use of building codes which can incorporate BOCA Codes (Building Officials and Code Administrator), NFPA Codes (e.g., NFPA 10, 30, 45 and 101), and UBC (Uniform Building Code).

In addition to OSHA and building code requirements, hazardous material requirements are also promulgated by the DOT (49 CFR 171-179 and 14 CFR 103).

Management Issues

In order to effectively manage chemicals, small labs should establish a program based on the following three principals:

- Minimize Exposures Take the necessary precautions when working with and storing chemicals. As a means of minimizing the potential for exposure, pursue opportunities for product substitution.

- Do Not Underestimate Risks Ensure that the risk associated with each chemical is assessed, understood and communicated. It is prudent to assume all chemicals are hazardous and handle them accordingly.

- Use Proper Control Measures Eliminate the hazard through engineering controls, personal protective equipment, and administrative procedures. Ensure that all staff are properly trained in accordance with regulatory requirements (e.g., Laboratory Standard) so that they can operate safety at their job.

The following are key management issues for the storage and handling of hazardous materials including hazardous chemicals, flammable liquids, and compressed gases. Regulations regarding the proper storage of hazardous materials are complex. The information provided below is not comprehensive. Small lab managers should review OSHA and other requirements and guidelines described above to ensure that all requirements are being meet and that hazardous materials are being managed in accordance with prudent practices.

The Chemical Hygiene and Hazard Communication Plan

29 CFR 1910.1450 and 1910.1200 establish requirements for the communication of chemical hazards to employees in the workplace. The programs include a number of common elements. These are:

- Establishment of documented programs. For labs subject to the Lab Standard, this is in the form of a Chemical Hygiene Plan (CHP);

- Preparation and periodic update of an inventory of all hazardous chemicals;

- Labeling of all containers of hazardous chemicals (including materials transferred from the manufacturer’s container to end user container such as spray bottles);

- The availability of Material Safety Data Sheets (MSDS’s) for workers on all shifts and in all locations;

- Employee chemical hazard training and documentation; and

- Processes to review and update the program on a periodic basis.

The Lab Standard also requires that a Chemical Hygiene Officer (CHO) be designated by the lab to implement and maintain the program.

The Chemical Inventory

A chemical inventory should be prepared and maintained. The inventory is important in complying with OSHA requirements such as the Lab Standard and EPA requirements such as those under EPCRA (see Emergency Planning and Community Right-To-Know, Section 3.9). The inventory can also be helpful in conserving space, saving economic resources, and promoting P2 (see Hazardous Wastes, Section 3.3). Inventories should include chemical names, storage locations, quantities, and hazard information. Individual inventories should be maintained in each lab and storage area with a roll-up inventory maintained by the CHO or other appropriate environmental staff.

Chemical Storage in the Lab

Centralized chemical storage is recommended. Chemical storage inside labs should be limited to those chemicals and quantities necessary to complete task requirements. Key consideration for lab storage and handling include:

- Chemicals should not be stored on floors or benches since they could be knocked over. Storage on open shelves should be avoided. When necessary, lips or restraining devices should be used. Do not store chemicals in the lab above eye level;

- Chemicals should be segregated according to chemical classes and compatibility first. Then they can be stored by a convenient finding method such as alphabetically. For example, acids should be kept separate from bases, oxidizers from organics, and cyanides from acids. Physical separation should be provided for reactive chemicals. Use secondary containers in storage areas if available space does not allow incompatible materials to be properly separated;

- Properly store flammable and combustible materials in accordance with NFPA 45 and NFPA 30 (see further descriptions below);

- When possible, segregate toxic chemicals from other chemicals and store in closed cabinets. Label the cabinets “TOXIC CHEMICALS” or with a similar warning;

- Maintain chemicals per manufacturer requirements;

- Ensure containers are labeled in accordance with the OSHA Laboratory Standard;

- Make sure containers are closed when not in use;

- Use secondary containment such as acid carriers when transporting liquid chemicals more than a very short distance; and

- Central chemical storage areas (e.g., rooms) require specific design and equipment such as construction materials, lighting, ventilation, fire extinguishers, and housekeeping procedures such as aisle space.

Flammable and Combustible Liquids

Additional requirements apply to those chemicals that are classified as flammable or combustible liquids. These materials must be stored in accordance with NFPA 45 in labs and NFPA 30 in other locations.

- Regardless of experimental or production requirements and even when NFPA allows higher quantities, prudent practice is that the quantity of these materials in a lab room not exceed a total of 60 gallons or one months supply (for all such chemicals combined);

- Flammable and combustible liquids should be stored in glass, metal or plastic containers that meet NFPA requirements. More than 10 gallons of flammable and combustible liquids should be stored in a flammables cabinet or specially designed room. Prudent practice is to store these materials in a flammables cabinet when ever possible;

- Storage in flammable cabinets must not exceed design quantities (e.g., 60 gallons). Cabinets should be properly vented if there is the potential for the buildup of hazardous vapors; and

- Refrigerators and freezers used to store flammable liquids should be explosion proof or “lab safe” in accordance with NFPA 45.

Highly Reactive Chemicals

Labs that use highly reactive chemicals should take measures to ensure that these substances are handled properly. Due to the volatile and explosive nature of this class of chemicals, it warrants special attention. The following guidelines should be followed when using and storing highly reactive substances:

- Consider the storage requirements of each highly reactive chemical prior to purchase and make sure that staff are trained to store it safely;

- Obtain and review the Material Safety Data Sheet or other chemical safety information to ensure that staff are aware of the hazards and storage requirements;

- Purchase small quantities of the chemical that staff will need for the short term. Try not to exceed a three-month supply;

- Label, date, and inventory all highly reactive materials as soon as they are received. If staff must transfer the chemical from its original container into another container, make sure it is labeled with the name of the chemical, and the words “DANGER! HIGHLY REACTIVE MATERIAL.” For water reactive chemicals include the warning “DO

- NOT USE WATER TO EXTINGUISH FIRE.” Note: OSHA may require special labels disclosing all hazards on repackaged containers;

- Do not open a container of highly reactive material that is past its expiration date;

- Do not open a liquid organic peroxide or peroxide former (e.g., picric acid) if crystals or a precipitate are present;

- Segregate the following highly reactive materials:

- Oxidizing agents from reducing agents and combustibles,

- Powerful reducing agents from readily reducible substrates, and

- Acids from reducing agents;

- Store highly reactive liquids in trays large enough to hold the contents of the bottles;

- Store peroxidizable materials away from heat and light;

- Do not use metal spatulas to handle peroxides because ontamination by metals can lead to explosive decomposition. Use ceramic, Teflon, or wooden spatulas;

- Avoid friction, grinding, and all forms of impact near peroxides, especially solid peroxides and diazomethane solution (used in methylation of some pesticides). Glass containers that have screwcap lids or glass stoppers should not be used. Instead, use polyethylene bottles with screw-cap lids;

- Store materials that react vigorously with water away from possible contact with water;

- Store thermally unstable materials in a refrigerator. Use a refrigerator with these safety features:

- Alarm to warn when temperature is too high,

- Spark-proof controls on the outside, and

- Magnetic locked door;

- Store liquid organic peroxides at the lowest possible temperature consistent with the solubility or freezing point. Liquid peroxides are particularly sensitive during phase changes;

- Inspect and test peroxide-forming chemicals periodically; and

- Store containers in cabinets that are designed to hold that type of waste.

Compressed Gases

Compressed gas cylinder storage should meet the requirements in the Compressed Gas Association Pamphlets C-6 1968 and C-8 1962.

- Properly label the cylinders with their contents; store upright and away from heat sources;

- Cylinders should be chained to the wall or otherwise secured from falling;

- Do not store cylinders so as to block exits, obstruct aisles, or otherwise interfere with egress; and

- Cylinders should be separated based on their contents. Incompatible materials (e.g., oxygen and propane, chlorine and helium) should be segregated. In addition, full, partially full and empty cylinders should be labeled as to their status and separated.

Pollution Prevention and Hazardous Materials Storage

P2 and waste minimization for hazardous chemicals starts with the substitution of less hazardous substances (see Hazardous Wastes, Section 3.3). Sometimes this is difficult in a lab environment where researchers may be unwilling to change because they are concerned about the performance of the substitute in their experimentation. This can often be overcome through a team effort involving the CHO, environmental staff, purchasing staff and the researcher. In this setting, limitations and concerns can be clearly articulated and more easily addressed. Other opportunities include:

- Maintaining an accurate inventory that can be shared throughout the facility. Using this inventory, chemicals can be shared and expiration dates can be tracked;

- Purchasing of only the smallest amounts needed. Often, the additional cost associated with the smaller or custom purchase is less than the cost of expired or unused chemical disposal;

- Establish a centralized purchasing program to ensure full utilization of chemical products;

- Order reagent chemicals only in amounts needed;

- Maintain a limited inventory of chemicals on hand so those chemicals do not expire or deteriorate and necessitate disposal;

- Scale down experiments or procedures. Over the last decade, microscale chemistry has come to be considered a proven technology. It can reduce the quantity of chemical reagents used by a factor of 100 to 1000. Lab safety can be improved due to the reduction in exposure to organic vapors, for example, and spill preparedness is easier. Less chemical storage space is needed and chemical inventory management requires less labor. Cost reductions also result even if per-unit reagent costs increase due to purchasing smaller containers, the annual dollar savings on total purchases usually offsets this. Reduce or eliminate the use of highly toxic chemicals in lab experiments;

- Increase the use of instruments that require less reagent or smaller or fewer samples;

- Use less solvent to rinse equipment;

- Review the use of highly toxic, carcinogenic, reactive, or mutagenic materials to determine if safer alternatives are feasible; and

- If feasible, consider using computer simulation or modeling to replace wet chemistry.