Green material design and development refers to the process of creating materials that are environmentally friendly throughout their lifecycle. This approach aims to minimize the negative impact on the environment and human health while maximizing resource efficiency and sustainability. Green materials are typically characterized by their low carbon footprint, reduced energy consumption, use of renewable resources, and safe disposal or recycling options.

Here are some key aspects and strategies involved in green material design and development:

- Material Selection: Choosing materials that have a lower environmental impact is a crucial step. This includes selecting materials with minimal resource extraction, lower energy requirements in production, and reduced emissions or pollutants.

- Renewable and Recycled Materials: Prioritizing the use of renewable resources, such as bamboo, cork, or responsibly sourced wood, helps reduce dependence on non-renewable resources. Additionally, incorporating recycled materials, such as recycled plastics or reclaimed metals, reduces waste and promotes a circular economy.

- Energy Efficiency: Designing materials that require less energy in their production, usage, and disposal stages is essential. This can involve optimizing manufacturing processes, utilizing energy-efficient technologies, or developing lightweight materials to reduce transportation energy.

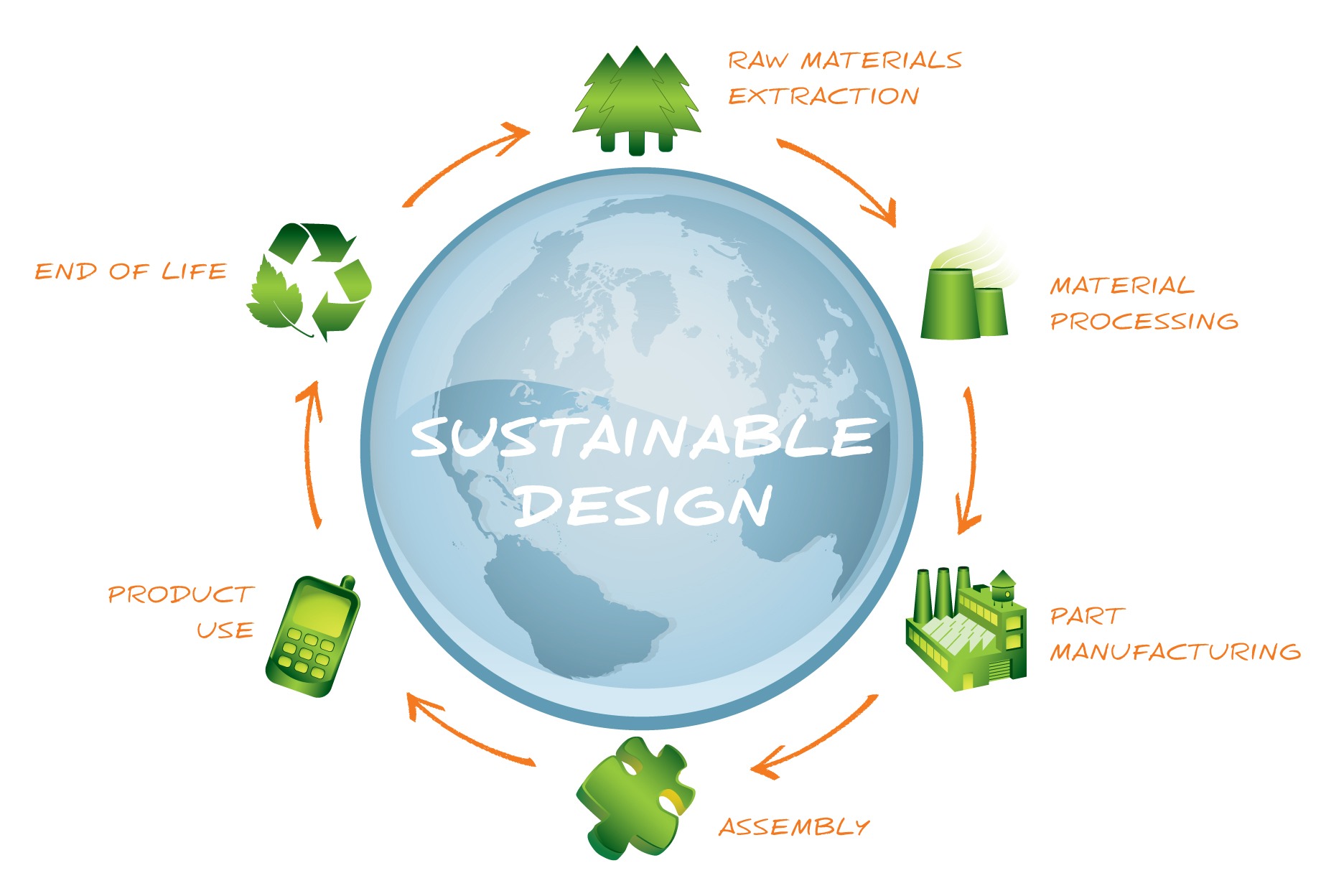

- Life Cycle Assessment (LCA): Conducting a thorough life cycle assessment helps evaluate the environmental impact of materials throughout their entire life cycle, from raw material extraction to disposal. LCA allows for identifying areas for improvement and making informed decisions during the design and development phase.

- Toxicity and Health Considerations: Green materials should be free from harmful chemicals, toxins, and pollutants that can negatively impact human health and the environment. This involves using safer alternatives to hazardous substances commonly found in traditional materials.

- Durability and Longevity: Designing materials to be durable and long-lasting helps reduce the need for frequent replacement, minimizing waste generation and resource consumption over time.

- End-of-Life Considerations: Planning for the end of a material’s life cycle is crucial. This can involve designing materials that are easily recyclable, compostable, or biodegradable, ensuring they can be properly managed and diverted from landfills.

- Collaboration and Research: Green material design and development require collaboration among various stakeholders, including designers, engineers, manufacturers, and researchers. Investing in research and development of new green materials and technologies is also essential for continuous improvement.

- Standards and Certifications: There are various standards and certifications available for green materials, such as GGBC (Global Green Building Council), Cradle to Cradle, and BREEAM (Building Research Establishment Environmental Assessment Method). Adhering to these standards helps ensure compliance with specific environmental and sustainability criteria.

By integrating these principles into material design and development processes, it is possible to create products that are not only environmentally friendly but also economically viable and socially responsible. Green materials contribute to a more sustainable future by reducing resource depletion, mitigating climate change impacts, and minimizing waste generation.