COURTESY : www.bcg.com/

Green factory

Industrial companies have an enormous carbon footprint. Their production and logistics operations account for more than half of all global carbon dioxide equivalent (CO2e) emissions from fuel combustion. Considering current trends, emissions from production and logistics would need to decrease by approximately 45% by 2030 to be on a path to meet the Paris Agreement’s 1.5°C target for limiting the global temperature increase. As longstanding environmental concerns intensify, industrial companies are feeling increasing economic pressure to tackle the problem.

Recognizing the need for action, leading companies are implementing initiatives to decarbonize their operations. Moreover, some companies have gone further and started to require their business partners in the supply chain to demonstrate a commitment to decarbonization as well. The result is a convergence of environmental and economic imperatives that all industrial companies must be prepared to address. The solution is a concept that we call “the green factory of the future,” in which the integrated application of decarbonization measures reduces net emissions to zero.

To better understand the opportunities and challenges that decarbonization presents, a BCG study examined expectations for and adoption of decarbonization measures in industrial operations. The study focused on the results of a global survey of nearly 1,200 operations executives from numerous producing industries. (See “About the Study.”) This survey was conducted before the COVID-19 pandemic spread globally. However, although the pandemic has altered some short-term priorities, the climate challenge and the urgency to respond to it remain unchanged. In the middle term, the actions described in this report will continue to be relevant and may even have gained significance. Indeed, as companies revamp their strategies to win the post-pandemic future, they have a unique opportunity to focus on climate action.

ABOUT THE STUDY

The study found that industrial companies want to reduce their carbon footprint, with more than three-quarters of them viewing decarbonization as a high priority. So far, however, most companies have struggled to achieve their goals. Only 13% of survey respondents say that their company has fully implemented decarbonization measures in their production and logistics. The biggest obstacle to more aggressive action seems to be concern that the initiatives will raise conversion costs.

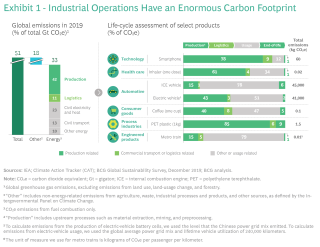

Industrial production and logistics operations account for more than half of global CO2e emissions from fuel combustion.

We believe that industrial companies should not regard environmental sustainability as a threat to economic sustainability. Indeed, as pressure intensifies to pursue decarbonization throughout the industrial supply chain, environmental and economic sustainability will become increasingly difficult to separate. Although the challenges are significant, the results of our study show that companies can implement win-win actions that benefit the environment and create financial value. The keys to success are to identify the most effective decarbonization measures and to evaluate the economic impact of adopting these measures in a way that considers factors beyond conversion costs—such as getting ahead of regulations, attracting investors, and winning new customers. By using a rigorous evaluation process, a company can ensure that environmental and economic sustainability go hand in hand in the green factory of the future.

WHY SUSTAINABILITY MATTERS IN OPERATIONS

Our study focused on environmental sustainability in industrial operations, comprising production and logistics. We gave special emphasis to greenhouse gas (GHG) emissions, which are predominantly CO2 but also include such gases as methane and nitrous oxide. (See “The Basics of Sustainability in Operations.”)

THE BASICS OF SUSTAINABILITY IN OPERATIONS

As noted earlier, industrial operations are responsible for a significant share of global GHG emissions. CO2e, the standard unit for measuring GHG emissions, estimates how much of a contribution a given quantity and type of GHG may make toward global warming. Production accounts for more than 40% of global CO2e emissions from fuel combustion, and commercial logistics accounts for more than 10%. (See Exhibit 1.)

The share of CO2e emissions attributable to production- and logistics-related activities depends on the product, as the life-cycle assessment in Exhibit 1 illustrates. For example, for a car powered by an internal combustion engine (ICE), the share of emissions attributable to production is relatively low (15%), whereas 78% of emissions result from operating the car. In contrast, for a battery-powered electric vehicle (EV), nearly 43% of emissions are attributable to production, mainly owing to battery production, which is quite energy intensive. For this reason, although it may seem counterintuitive, the lifetime emissions for EVs are almost the same as those for ICE vehicles. We based our life-cycle assessment for EV batteries on production in China, where battery producers and power companies depend, to a significant degree, on electricity from a power grid that relies on emissions-heavy hard coal, lignite, and natural gas. To calculate emissions from EV utilization, we used the global average power-grid mix.

Leading companies are taking action to reduce their operations’ carbon footprint. For example, the Volkswagen Group has announced that its ID.3 EVs will be the first model manufactured at its Zwickau plant using carbon-neutral production. The automaker hopes to achieve carbon-neutral production for its entire fleet by 2050.

Daimler has announced an even more aggressive time frame for decarbonization. The automaker wants its entire fleet of passenger cars to be carbon neutral by 2039. It also intends to make its assembly plants carbon neutral by 2022, by transitioning from coal-based electricity to energy generated exclusively from renewable resources. Looking beyond its own operations, Daimler is requiring its suppliers to adopt its standards for decarbonization. Other large automakers have imposed similar requirements. As a result, having a climate-friendly production process in place has become table stakes for winning their business.

Various stakeholders are demanding that companies transition to environmentally sustainable operations. For example, BlackRock, a leading investment management company, has announced that sustainability will become its “new standard for investing” and an integral part of its strategy for increasing long-term returns.

Industrial companies’ management teams seem to recognize the need for action. Among study participants, more than 75% say that carbon neutrality is either the most important initiative at their company or one of the top three initiatives. When asked their main reason for seeking to decarbonize operations, 28% of respondents cite the need to meet regulatory requirements, and 25% point to reducing conversion costs. Only 15% say that customer demand is their primary reason.

ENVISIONING THE GREEN FACTORY OF THE FUTURE

Given the clear need for action to reduce GHG emissions in operations, what targets are reasonable? Companies usually discuss goals for reducing GHG emissions in terms of meeting the 1.5°C target derived from the 2015 Paris Agreement, in which more than 190 countries committed to taking steps to limit the global average temperature increase to 1.5°C above pre-industrial levels. To achieve the 1.5°C target, countries would need to reduce their overall net emissions to zero by around 2050, with incremental reductions along the way. Unfortunately, many countries—including the top five emitters (China, the US, the European Union, India, and Russia)—are falling short of meeting their goals. The concrete actions we discuss below can bolster efforts to achieve the target.

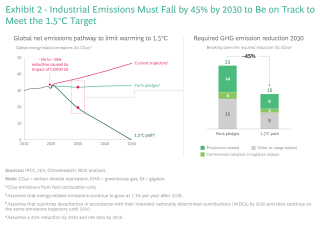

As of 2019, global GHG emissions from fuel combustion totaled approximately 33 gigatons of CO2e (Gt CO2e). To be on a path to achieve the 1.5°C target, net emissions would need to fall to 18 Gt CO2e by 2030. However, extrapolating the current trend for global emissions to 2030 yields emissions of 33 Gt CO2e—a shortfall of 15 Gt CO2e against the incremental goal for meeting the 1.5°C target. To close this gap by 2030, GHG emissions from production and logistics would have to decrease by 45% relative to the current trend. (See Exhibit 2.) From that point, incremental reductions would have to continue for two more decades until net emissions dropped to zero.

How can a company help close the gap? To reduce its operations-related GHG emissions, a company can avoid, reuse or store, or offset or compensate for emissions. Each category of actions includes one or more abatement levers. For each lever, we present examples of the most important applications in industrial operations, as confirmed by study participants. (See Exhibit 3.)

Avoid. A company can avoid emissions by increasing its energy efficiency or by changing how it conducts or powers its operations:

- Increase efficiency. A company can use several approaches to increase its efficiency. First, to improve the energy efficiency of its operations, it can apply operational excellence levers that improve operational performance and emission levels simultaneously. The primary levers include reducing scrap rates and machine idling time and optimizing layouts to reduce the complexity of logistics processes. These actions enable a company to directly cut emissions by reducing waste, process emissions, and energy consumption. A company can also take steps to generate, use, and recover heat more efficiently. Examples include using high-efficiency burners that also recover waste heat, introducing heat exchangers that connect co-located users, or installing heat pumps that raise the temperature of waste heat to a usable level. Second, to minimize the distances that parts travel in its supply chain, a company can use intermodal transportation to optimize its logistics network and materials handling. Third, to reduce consumption, it can deploy energy monitoring, management, and steering systems (for example, deploying a stop-and-go mechanism for machinery that triggers a shutoff when the equipment is not in active use, or installing air pressure systems to facilitate leak detection). One way to increase logistical efficiency is to replace human control with an automated system that guides or controls vehicles. For instance, Rio Tinto, one of the world’s largest metals and mining companies, has launched a project called AutoHaul to automate trains that transport iron ore to its port facilities in Western Australia. The system autonomously conducts nearly two-thirds of all train kilometers, permitting more-efficient operations that have reduced fuel use by 13%.

- Change processes or technology. A company can change its core production processes or technology in order to substitute a low-emissions process for a high-emissions process. For example, SSAB, which seeks to achieve carbon-neutral steel production by 2026, is cutting CO2 emissions by replacing the coal-coking process traditionally used for ore-based steelmaking with a process powered by fossil-free electricity and hydrogen. Other examples include using rail transportation instead of trucks and replacing conventional manufacturing with 3D printing to minimize waste, packaging, and transport emissions. For instance, by the end of 2019, Boeing had used 70,000 3D-printed parts in its commercial and defense aircraft.

- Switch fuel or power source. A company can use other energy sources in place of fossil fuels and fossil- fuel-based power generation. Options include using electricity generated from renewable sources (for example, solar and wind) rather than coal, using internal combined heat and power (known as CHP) fueled by biomass in place of natural gas, and using electricity rather than diesel to power forklifts. For example, Mercedes-Benz’s Bangkok plant, which is on track to achieve carbon-neutral production starting in 2022, uses large solar-powered systems on its roof to generate electricity. The company stores the excess power in a stationary second-life battery storage system that uses recycled electric vehicle batteries.

One way to increase logistical efficiency is to replace human control with an automated system that guides or controls vehicles.

Reuse or Store. A company can apply two main levers to reuse or store carbon emissions:

- Recycle and remanufacture. A company can convert waste into reusable material (recycling), or it can reuse existing parts to produce new equivalent products (remanufacturing). For recycling, one prominent use case is the introduction of a closed-loop system involving local recycling of materials (often plastics) to create new products. Using recycled materials requires significantly less energy than using virgin materials does. For instance, recycling aluminum requires up to 95% less energy than producing the primary metal from bauxite, and thus avoids the corresponding emissions. A good example from the construction industry involves the efforts of HeidelbergCement, which has cofounded a recycling company called Rewinn that produces construction aggregates by recycling concrete from demolition sites. The company has the capacity to produce up to 250,000 metric tons of aggregates annually through recycling. As an example of remanufacturing, a heavy-duty engine manufacturer offers its clients a choice for machine maintenance and refurbishment: they can opt for newly manufactured spare parts or for fully functional used parts at a lower price.

- Capture carbon, and use or store it. A company can capture carbon emitted as a byproduct of production processes and use or store the carbon to prevent its release. For example, Thyssenkrupp Steel plans to reuse carbon through a new method it is developing called Carbon2Chem. This method converts gases produced during steel production into base chemicals that can be used to make fertilizers, plastics, or fuels. Meanwhile, Carbon Recycling International, an Icelandic company, has developed a technology that helps transform CO2 emissions into methanol via direct hydrogenation of captured CO2. The company plans to deploy this technology at scale in the chemicals industry as the first step toward commercializing it.

Offset or Compensate. A company can compensate for its CO2 emissions through offsetting measures. Such measures can be unrelated to the company’s own production or logistics. For example, Willmott Dixon, a UK-based construction company, has partnered with Natural Capital Partners to select and execute carbon-reducing projects that provide social benefits to local communities. These benefits advance the goals of the foundation that Willmott Dixon has established to promote social causes. The projects include preserving 47,000 hectares of a carbon-dense tropical peat swamp in Borneo that was in danger of being converted into palm oil plantations. Most companies, however, view offsetting as a complement to other abatement levers, rather than as a standalone solution with significant independent impact. For example, Bosch is using offsetting as an interim solution to accelerate its progress toward carbon neutrality. As the company increases the share of renewable energy in its production through 2030, it will compensate for unavoidable CO2 emissions through carbon offsets.

COMPANIES LAG BEHIND THEIR AMBITIONS

More than 60% of study participants say that their company plans to implement decarbonization measures. And more than 90% of participants say that their company will dedicate a portion of its manufacturing investment budget to decarbonization measures in the next three years. Among those participants, roughly half say that the company will spend more than 10% of its available manufacturing investment budget on decarbonization in the next three years.

To realize their ambitions, companies must improve how they implement their plans. Although we see promising examples and high ambitions, many previous efforts to implement decarbonization measures have not been very successful. Only 13% of participants report that their company has fully implemented decarbonization measures in their production and