Green building materials for construction

Courtesy : www.conserve-energy-future.com/

We are traditionally used to using earth bricks, concrete, and wood in construction. They have been, and continue to be used in everyday construction, meaning the continued destruction of trees for timber, and the mining of resources to produce cement for binding sand, gravel, and bricks. For a better world, there are new processes, and sustainable as well as green building material alternatives that can be used in construction today. Here are the top 15 sustainable and green building materials in construction.

Contents [show]

Sustainable and Green Building Materials That Can Be Used in Construction

1. Bamboo

Bamboo is considered one of the best eco-friendly building materials. It has an incredibly high self-generation rate, with some being reported to have grown up to three feet within 24 hours. It continues spreading and growing without having to be replanted after harvest. Bamboo is a perennial grass and not wood and grows on every continent, except Europe and Antarctica.

It also has a high strength-to-weight ratio, even greater comprehensive strength than concrete and brick, and lasts incredibly long. It is, therefore, the best choice for flooring and cabinetry. Unfortunately, bamboo requires treatment to resist insects and rot. If left untreated, bamboo contains a starch that greatly invites insects, and it could swell and crack after absorbing water.

2. Precast Concrete Slabs

The slabs are formed at a manufacturer’s site and are shipped in whole sections to construction sites. Some are made entirely of concrete but have large hollow air spaces, like concrete blocks. Precast concrete slabs are used for walls and building facades as they hold up well to all sorts of weather, while others can be used for floor and flat roofs.

Concrete is an excellent way of controlling heat within a building and is affordable as a building material. The sustainability of precast concrete slabs is higher than many traditional concrete options as the slabs often take much less energy to produce and assemble. Precasting concrete also allows the material to properly cure in a controlled environment, rather than exposing it to a variety of unfavorable weather conditions while curing at a construction site. As such, precast concrete slabs avoid cracks and structural faults within the concrete and eventual demolitions.

3. Cork

Just like bamboo, cork grows very quickly. It can also be harvested from a living tree, which continues to grow and reproduce more cork, which is a tree bark. Cork is resilient, flexible and reverts to its original shape even after enduring sustaining pressure. Its resilience and resistance to wear, makes it a common element in floor tiles.

See also Green Architecture: Materials Used and Principles of Green Architecture

It also excellently absorbs noise, making it perfect for insulation sheets, and due to its excellent shock absorption qualities, it perfect for sub-flooring. It can also be a good thermal insulator as it is fire resistant, especially if untreated, and does not release toxic gases when it burns. Cork, in being nearly impermeable, does not absorb water or rot.

Unfortunately, it can only be sourced from the Mediterranean, making shipping it a bit costly. Fortunately, it is extremely light and only requires less energy and emissions to ship.

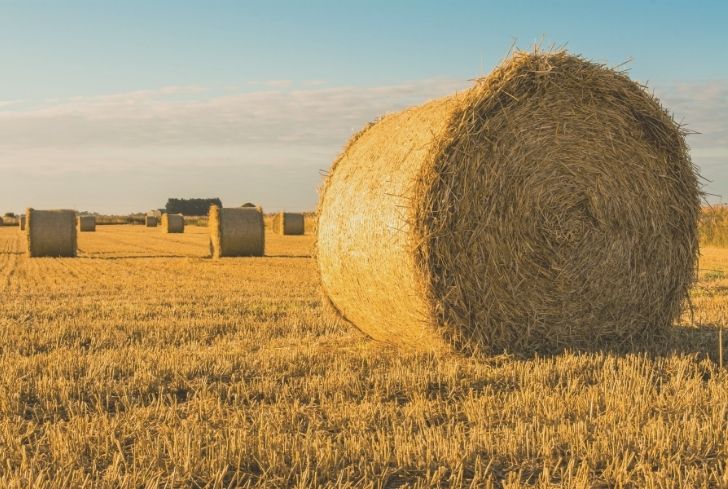

4. Straw Bales

It is another green building material that can be used as a framing material. They have good insulation properties and can act as soundproof material. It can also be used as fill material in between columns and in beams framework/ as they cannot allow air through, they can have some fire resistance properties.

Straw can be harvested and re-planted easily with minimal environmental impacts. Making straw into bales also has very low influence. They can also be placed in walls, attics and ceilings, to contribute to cooler the house in the summer and warmer temperatures in the winter.

5. Recycled Plastic

Rather than sourcing, mining and milling new components for construction, manufacturers are using recycled plastic and other ground-up trash to produce concrete. The practice is reducing greenhouse gas emissions and is giving plastic waste new use, rather than clogging landfills and contributing to plastic pollution.

A blend of recycled and virgin plastic is also used to make polymeric timbers, for use in making fences, picnic tables and other structures, at the same time, saving trees. Plastic from two-liter bottles can be spun into fiber for the production of carpets. Reused plastic can also design products such as cable pipes, roofs, floors, PVC manholes, and PVC windows.

6. Reclaimed Wood

Using reclaimed wood is one of the most environmentally responsible ways to save trees and reduce the amount of lumber in landfills. Reclaimed wood can be found in retired barns, excavation companies, home remodeling contractors and companies, salvage yards, and shipping crates and pallets.

Reclaimed wood is good for structural framing, cabinetry, and flooring. It is lightweight but has less strength and each piece’s integrity should be assessed and chosen for an appropriate project. Also, most wood is susceptible to insects and degradation, meaning it needs reinforcement and additional treatment.

7. Reclaimed or Recycled Steel

Steel can be used for the framing process, in place of wood, increasing the durability of a structure against earthquakes and high winds. A 2,000-square foot house requires about 50 trees to build, but a frame made from recycled steel requires the steel equivalent of just six scrapped cars.

Steel is 100% recyclable and significantly reduces the ecological impact of new construction. Mining, heating and shaping products made from aluminum and steel requires a lot of energy, but properly and efficiently reusing or recycling them into new products, lowers the energy used, and makes the material more sustainable, the recycled metal is long-lasting and does not require frequent replacements.

See also Sustainable Mining Solutions with Neoloy® Geocells

It does not burn or wrap and is therefore perfect for roofing, building facades and structural support. Additionally, recycled steel is water- and pest-resistant.

8. Plant-based Polyurethane Rigid Foam

Rigid foam has for long been used as insulation material in building. It was first used after a top manufacturer of surfboard material, was fined by the EPA, and subsequently put out of business, for using a toxic material. The new surfboard material was made from plant-based polyurethane rigid foam, which came from bamboo, kelp and hemp, rejuvenating the surfboard industry.

It is now in use in the manufacturing process including that of turbine blades and furniture. The material is rigid and relatively immovable, meaning it can be used for insulation. Additionally, it offers protection against mould and pests. It is also heat resistant, protects against mould and pests, and can be perfect as sound insulation.

9. Sheep’s Wool

Sheep’s wool is a great alternative to chemical-laden insulation. It insulates the home just as well as conventional insulation and requires less energy to manufacture. Sheep’s wool can increase energy efficiency and soundproof your structure. It does not degrade nearly as quickly as other insulation materials like straw and compared to some natural insulators such as cotton, sheep’s wool is more prevalent, can be harvested more easily and regenerates quickly.

Unfortunately, it is not the most affordable insulator. It also has to be treated to ward off insects and prevent the growth of fungi. Such treatment might make sheep’s wool less eco-friendly, depending on the chemicals used.

10. Rammed Earth

It is a technology that has been used throughout human civilization for thousands of years and lasts a very long time. It is a popular and affordable solution to creating steadfast foundations, floors and walls, through natural materials such as chalk, earth, gravel or lime, and then compacting them.

When pressed tightly in wooden forms, it creates walls that have a similar feel to concrete. Buildings made from rammed earth are made safer or fortified by the use of rebar or bamboo. Mechanical tamper can greatly reduce the amount of labor required to create sturdy walls. Rammed earth walls and floors can be used as thermal storage, allowing the sun to warm them in the day and slowly release the warmth in the cooler evenings.

11. HempCrete

It is a concrete-like material created from the woody inner fibres of the hemp plant. The fibres are bound with lime to create concrete-like shapes that are strong and light. Hemp concrete blocks are lightweight, dramatically reducing the energy used to transport the blocks. Hempcrete is sturdy, has good thermal and acoustic insulation qualities and is fire resistant. Additionally, its biggest sustainable property is that it is CO2 negative, meaning it absorbs more CO2 than it emits. Hemp itself is a fast-growing and renewable resource.

See also Is Burlap Biodegradable? (And Composable?)

12. Mycelium

It is a building material that is actually natural. Mycelium is a natural unicellular organism that comprises the root structure of fungi and mushrooms. It could be encouraged to grow around a composite of other natural materials, such as ground-up straw, in molds or forms. It is then air-dried to create lightweight and strong bricks or other shapes.

Combined with pasteurized sawdust, mycelium could be formed into almost any shape, and be used as a surprisingly sturdy building material. There is the potential for creating bricks and uniquely-shaped building segments that are both strong and lightweight. The mushroom-based building material can withstand extreme temperatures, making it an organic and compostable alternative to home insulation, Styrofoam and even concrete.

It is a relatively new material and it uses recycled materials such as steel dust from the steel industry, or ferrous rock leftover from industrial processes, usually sent to the landfill. It creates a concrete-like building material, stronger than the concrete itself. It traps and absorbs carbon dioxide as part of its drying and hardening process.

This makes ferrock carbon neutral and a lot less CO2 intensive as compared to traditional concrete. It is a viable alternative to cement and can be mixed and poured to form driveways, staircases, pathways, and more structures. Some researchers believe ferrock is more resilient to weather than concrete.

14. Timbercrete

This is an interesting building material and is made from a mix of sawdust and concrete. It is lighter than concrete and reduces transportation emissions. The sawdust also reuses a waste product and replaces some of the energy-intensive components of traditional concrete. Timber concrete could also be formed into traditional shapes like pavers, bricks and blocks.

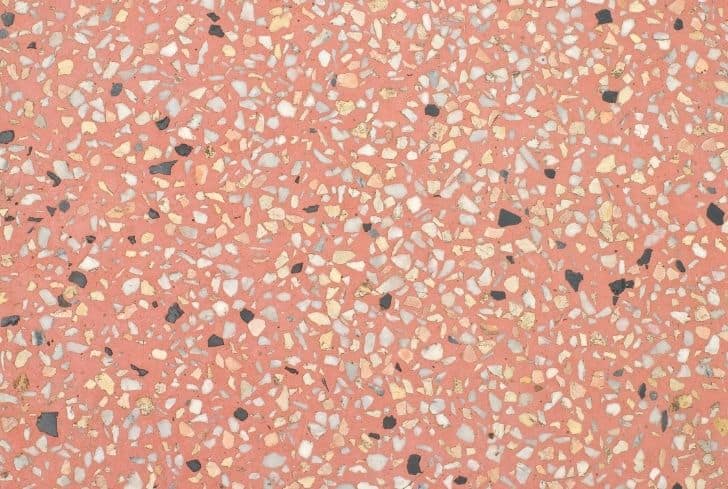

15. Terrazzo

This is a mosaic style of flooring where small pieces of marble or granite are set in polished concrete or epoxy resin. When well maintained, terrazzo floors can last up to 40 years without losing their brilliance. The original terrazzo was set in cement and was modeled after 20th-century Italian work.

Today, 90% of terrazzo floors are made with an epoxy resin. A company like Terrazzo & Marble Supply company manufactures ‘forever floors’ from their own epoxy, which incorporates materials like brass, aluminum and zinc, along with recycled glass, beer bottles, marbles and porcelain.

A terrazzo floor might be more expensive than carpets, but you will have to replace carpets. Terrazzo floor, on the other hand, can last for over four decades, making it a sustainable building material. Additionally, before pouring terrazzo into place, you can use the color of your choice and make the floor of your choosing. It makes for easy-to-clean floors, which can also be installed in high-traffic areas like schools, airports, and stadiums.