Courtesy : sciencedirect.com

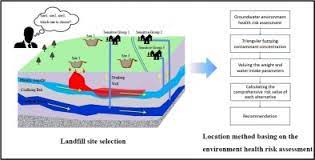

Environment assessment and site selection

The commitment of international governments to limit global warming to 2 °C has led to an increased awareness and interest in sustainability from various stakeholders. Especially the ecological performances of corporations and their products regarding limiting greenhouse gas emissions (GHG) receives increasing attention.

In Germany, almost 25% of the annual GHG emissions is generated by the industry sector primarily for the respective raw material production. The production of aluminum, which is mainly used for applications in the mobility sector, accounts for 1% of the entire German GHG emissions. However, currently, the assessment focus is set on the vehicle use phase. And, so far little attention is paid on the material production where about 75% of the value adding process of a car takes place in upstream supply chains. Current supplier selection decision making is dominated so far mainly by cost and quality factors. To integrate CO2e as an additional decision criteria, comparable site-specific CO2e emission data from suppliers is essential, but currently not existent.

In order to close this gap, a model has been developed to assess the performance of raw material manufacturers on a site-specific level based on publicly available data only. The developed model is applied to all four primary aluminum manufacturing sites in Germany that produce via the electrolytic reduction of virgin aluminum oxide. The estimated site-specific results of the application range between 13,689 and 14,946 kgCO2e/ton of raw aluminum and demonstrate different levels of internal process know-how, process integration and optimization in the production process of raw aluminum.

In consequence, there is an opportunity to reduce GHG emissions (up to −8.4%) for automotive and other manufacturing companies (e.g. the construction industry) by selecting more environmentally efficient suppliers for raw material and particularly aluminum.