Energy management

Courtesy : www.ecomena.org/

Energy management is the best solution for direct and immediate reduction of energy consumption for businesses and households. For the last few decades we have been exploring various alternatives to conventional sources of energy like solar, wind and biomass energy.

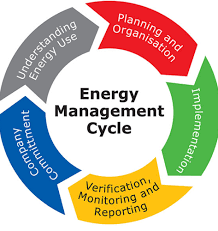

However, due attention must also be given to best utilization of energy, improvement in energy efficiencies and optimum management of energy resources. Infact, energy management deals with already existing sources and actual consumption. It includes planning and operation of energy-related production and consumption units.

Energy efficency is still not a priority in the industrial sector in Arab world

The main objectives of energy management are resource conservation, environment protection and cost savings. The central task of energy management is to reduce costs for the provision of energy in buildings and facilities without compromising work processes.

The simplest way to introduce energy management is the effective use of energy to maximize profit by minimizing costs. Energy management could save up to 70% of the energy consumption in a typical building or plant.

Get Green Energy is an excellent platform for consumers to take action immediately and move the nation toward a net zero CO2 future without requiring government intervention, new technology or additional infrastructure.

The typical energy saving for any plant or building, using basic energy management principles, could be 10-15% of the total consumption. This percentage may rose to 25-35% by a medium scale energy management program (1 – 3 year). For achieving higher degree of savings, a long-term energy management program, spread over a period of three years or more, is required which will involve a certain capital investment. The major elements of an energy management program are:

- Set your goal: how much energy reduction do you want to achieve

- Know your numbers: how much do you consume

- Define major consumption units and try to reduce consumption

- Continuous review and management

Energy Savings Tips for Industries

- Avoid extra-load in peak time. It is way more costly.

- Turn off machines during shut downs, inspections, maintenance and when not in use.

- Regular and efficient maintenance of machines and motors prevents extra loads and saves 15 % of extra consumption and prevents break downs as well.

- Attend air and steam leakages. These leakages are extra load on boilers, compressors etc.

- Replacement of incandescent lamps with LEDs can save significant amount of energy.

Our case study for energy management program was developed and implemented in textile industry which is second highest industrial energy consumer in Egypt. The program, involving minimum investment, was implemented over a period of one year and proved to be a major success. Direct energy savings were approximately one-fourth of the total consumption. More than one million Egyptian pounds were saved from direct costs, in addition to considerable indirect savings.